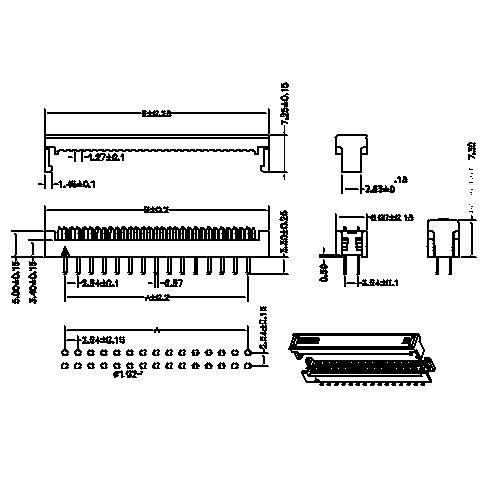

2.54MM DIP PLUG CONNECTOR (Mating Height 7.3MM Plug)

Get Latest Price| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW,FCA |

| Min. Order: | 1000 Piece/Pieces |

| Transportation: | Ocean,Air |

| Port: | SHENZHEN,SHENZHEN,SHENZHEN |

Select Language

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF,EXW,FCA |

| Min. Order: | 1000 Piece/Pieces |

| Transportation: | Ocean,Air |

| Port: | SHENZHEN,SHENZHEN,SHENZHEN |

Model No.: FDDS01-XXXXX

Brand: ANTENK

Interface Type: AC/DC

Housing: Plastic

Pin: Other

Poles: Other

Application: Other

Certification: Other

Gender: Other

Material: Brass

Support Card Number: Other

Operating Frequency: High Frequency

Classification: Wired Broadband Connection

| Selling Units | : | Piece/Pieces |

| Package Type | : | Bag packing,Tube packing,Reel packing |

| Download | : |

|

Shenzhen Antenk Electronics Co., Ltd. introduced a 2.54MM Dip Plug Connector (MATING HEIGHT 7.3MM).

Connector is an indispensable part of electronic equipment, it is blocked in the circuit or isolated circuit, set up a bridge of communication, so as to make the current flow, the circuit to achieve a predetermined function. Connector row pin form and structure is protean, with the application object, frequency, power, application environment, there are a variety of different forms of connector. Although there are many types of connectors, the basic performance can be divided into three categories: mechanical performance, electrical performance and environmental performance.

In terms of the function of connectors, the plugging force is an important mechanical property. Insertion force is divided into insertion force and pulling force (also known as pulling force), the requirements of the two are different. The maximum insertion force and minimum separation force are specified in the relevant standard, which indicates that, from the point of view of use, the insertion force is small (hence the structure of low insertion force LIF and no insertion force ZIF), while the separation force is too small, which will affect the reliability of the contact.

Another important mechanical property is the mechanical life of the connector. Mechanical life is actually an indicator of durability. They want to offer them for mechanical operation. It is based on a cycle of one insertion and one pullout, and is judged by whether the connector rows can normally complete their connection functions (such as contact resistance value) after the specified insertion and pullout cycle. The splicing force and mechanical life of the connector are related to the quality of the coating (sliding friction coefficient) and the dimensional accuracy (alignment) of the contacts.

Vibration and impact performance: vibration and impact resistance is an important performance of electronic connectors, especially important in special application environment, such as aviation and aerospace, railway and road transportation, it is an important index to test the robustness of mechanical structure and electrical contact reliability of electrical connectors. There are clear regulations in the relevant test methods. The peak acceleration, duration and shock pulse waveform, as well as the interruption time of electrical continuity shall be specified in the impact test.

Contact resistance: high quality electrical connectors should have low and stable contact resistance. The contact resistance of the connectors varies from a few milliohms to tens of milliohms. Factors affecting contact resistance include: resistivity of contact surface material, contact pressure, contact area, contact shape, surface conditions (relative cleanliness, roughness and hardness), current size, open circuit voltage at the contact point when the current is cut off, temperature and thermal conductivity of wire, etc.

The electrical strength, or voltage resistance, medium voltage resistance, is the ability to characterize the tolerance of rated test voltage between the contact parts of the connector or between the contact parts and the shell. Measurement method is between plug and socket contact element and contact element and shell in the indirect regulation time higher than its working voltage test voltage applied, to determine the correctness of the space between insulation, insulation, insulation structure, the flaws of the workpieces, examination electric connector row needles, tolerance, surge and similar phenomenon caused by the transient overvoltage

Insulation resistance is an index to measure the insulation performance between the contact parts of electrical connectors and between the contact parts and the shell. It is determined by the dielectric capacity of the dielectric, and the higher the insulation resistance, the better. Insulation resistance cannot be equated with withstand voltage, because insulation material is mixed by different material or composition, their insulation resistance is different naturally. Therefore, the measurement of insulation resistance cannot completely replace the measurement of cleanliness or nondestructive degree.

SPECIFICATION

Current Rating: 1.0Amp

Insulation Resistance: 1000MΩ min

Contact Resistance: 20mΩ max

Withstand Voltage: 500V AC/DC

Operating Temperature: -40°C to +105°C

Contact Material: Brass

Contact Plating: Au or Sn Over Ni

Insulator Material: PBT+30%GF UL 94V-0

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.